About Waxes

Wax is the name applied originally to naturally occurring esters of fatty acids and certain alcohols, but now applied to both natural and manufactured products resembling these esters.

Lube oil production is the source of petroleum wax. Only a small percent of crude oil gets produced into lube oil. Of that, only a small percent is wax. Oil is composed of pure hydrocarbons. Wax is defined as those hydrocarbons with carbon chains that number from about C10 to C50. The general difference between mineral oil and wax is if it's solid at ambient temperature, it's a wax, if it's liquid, it's oil with a certain pour point.

Petroleum waxes typically range from C10H38 to C50H102; paraffins going to C33H68 followed by micros and petrolatums. Petroleum wax has the generic formula CnH2n+2.

Paraffin Wax

Paraffin Wax

Microcrystalline Wax

Microcrystalline Wax

Petrolatums

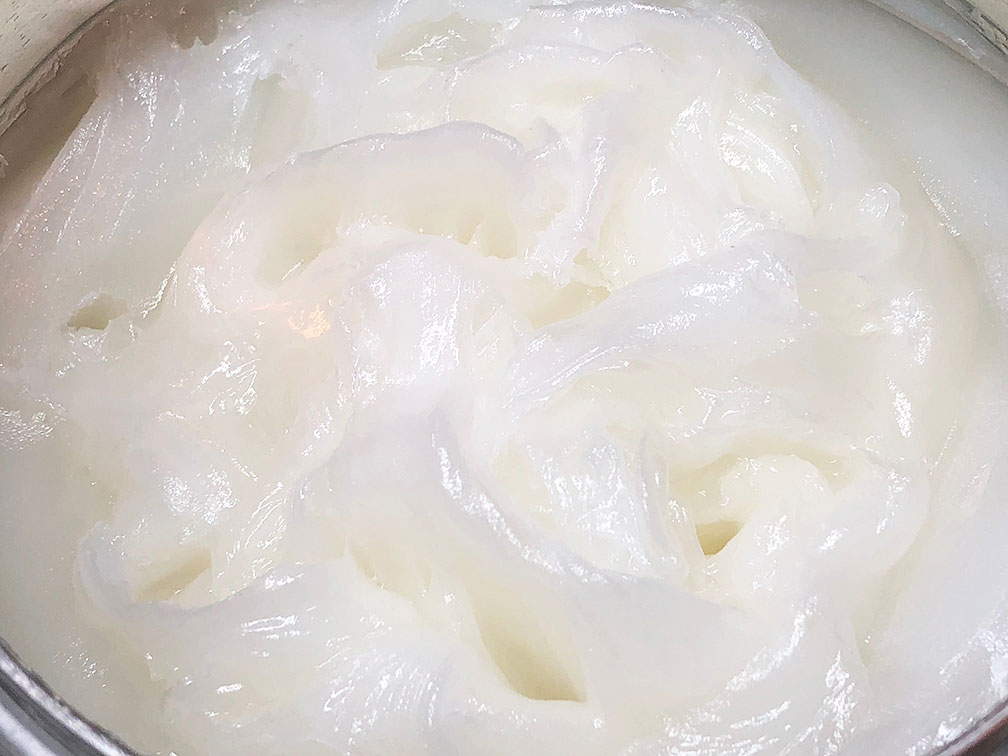

Petrolatums

Slack Wax

Slack Wax

- Paraffins, microcrystallines and petrolatums are all separated from crude petroleum. Paraffin can be fully refined to contain less than 0.5% oil. It is filtered to white and is FDA approved. Because of paraffin's superior burning and water vapor barrier qualities, it is used primarily in the candle, packaging and building board industries among many other markets.

- Microcrystalline waxes have better adhesive and elastic qualities and are used extensively in hot melt adhesives as well as in the packaging, printing ink and many other industries. Microcrystalline wax is refined from petrolatum, which comes from bright stock oil. It typically contains 41-50 carbon atoms.

- Petrolatums are often referred to as mineral jellies. Mineral jelly is an amorphous mixture of microcrystalline wax, mineral oil and paraffin wax. Straight unblended petrolatums are a by-product of bright stock oil, the heaviest viscosity lube oil, and are mostly used as feedstock for refining microcrystalline wax. Though petroleum waxes are not referred to as "natural", they are derived from the decomposition of organic matter and contain 15% hydrogen and 85% carbon.

- Synthetic waxes are primarily derived from natural gas or ethylene.

- Polyethylene (PE) waxes are made from ethylene produced from natural gas or by cracking petroleum naptha. Ethylene is then polymerized to produce waxes with various melt points, hardnesses and densities. Polyethylene molecular weights range from 500 to 3000 gms/mole. Oxidized PEs are readily emulsifiable, whereas non-oxidized PEs largely are not. High-density polyethylenes (HDPE) have a great deal of crystallinity and their molecules are tightly packed. Melt points range from 85°C to 141°C, and they are used in paints, textiles, coatings and polishes. Low-density polyethylenes (LDPE) display more toughness and exhibit better crystal formations. Densities are from 0.90 to 0.94 GMs/ml, and melt points range from 30°C to 141°C. LDPEs are used to improve mar and abrasion resistance, lubricity, slip and anti-blocking.

- Natural waxes are those from plants, insects and animals. Plant waxes occur on the exposed surfaces of many plants, protecting the plant against the excessive loss or gain of water. Beeswax is a substance secreted by the worker honey bee used for the construction of their honeycomb. Palm waxes and soy waxes have become increasingly popular for production of "all natural" candles. Beeswax is not just one material, but a huge complex mixture of different long chain molecules. Typical animal waxes are lanolin, or wool grease, and ambergris, a wax produced in the intestines of sperm whales and used in making perfumes.